3D-printing

The path from idea to prototype to a finished product is very short when working with Vink Plast.

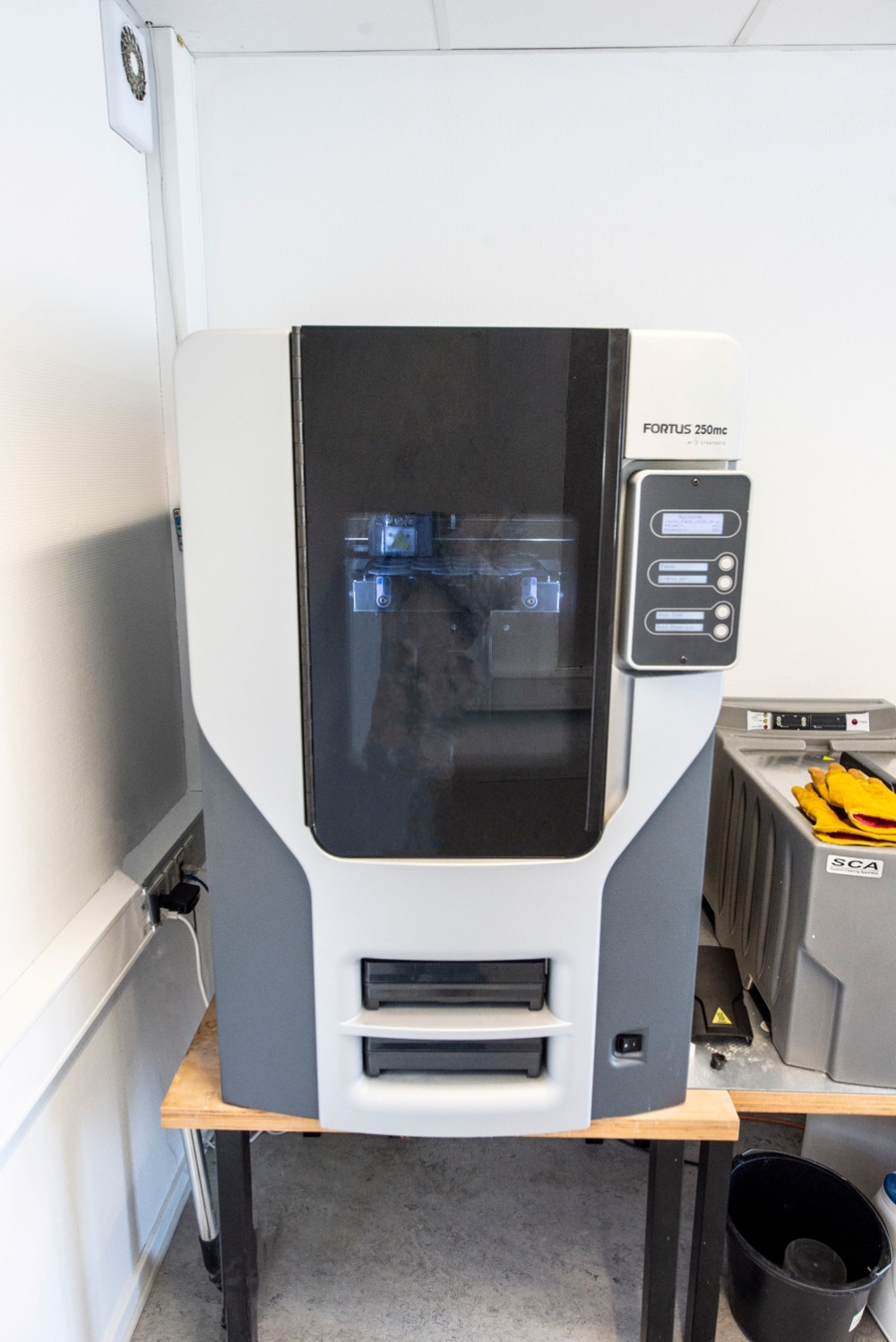

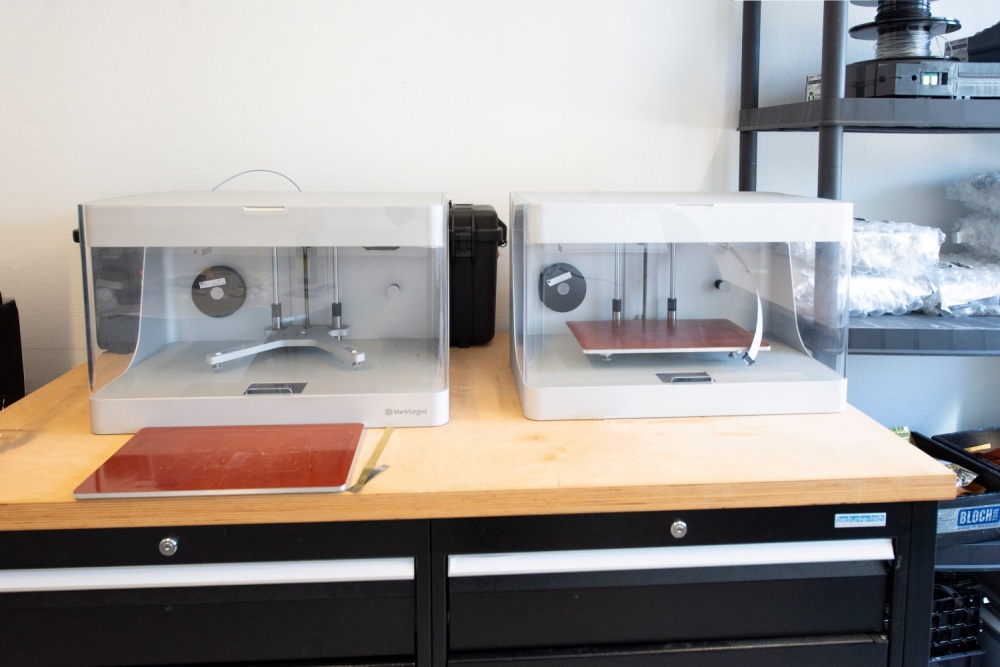

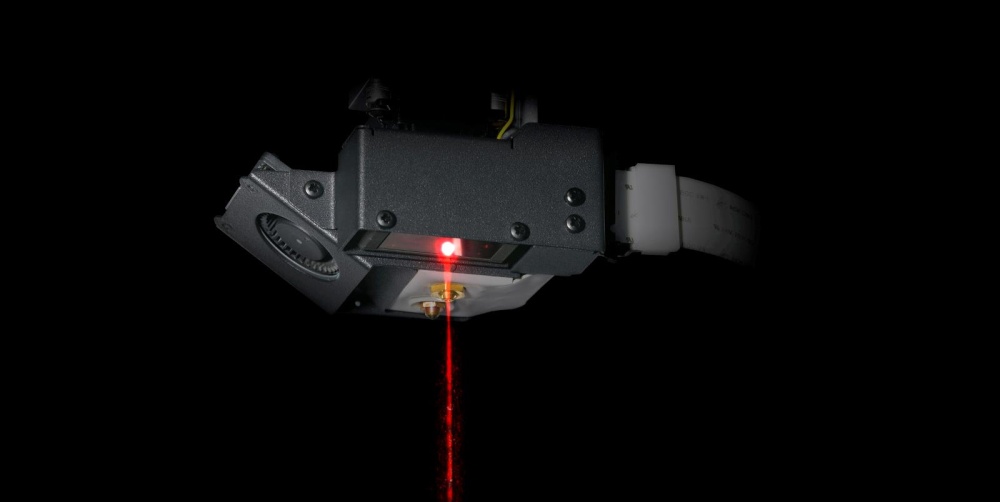

We currently have four 3D-printers available for prototyping. For example the Fortux 250mc, which is a reliable and flexible printer that can produce very precise components at a reasonable price. The printer is based on the Stratasys FDM technology (Fused Deposition Modelling). The method is a type of thermoplastic extrusion and is one of the leading technologies in additive manufacturing.

Materials

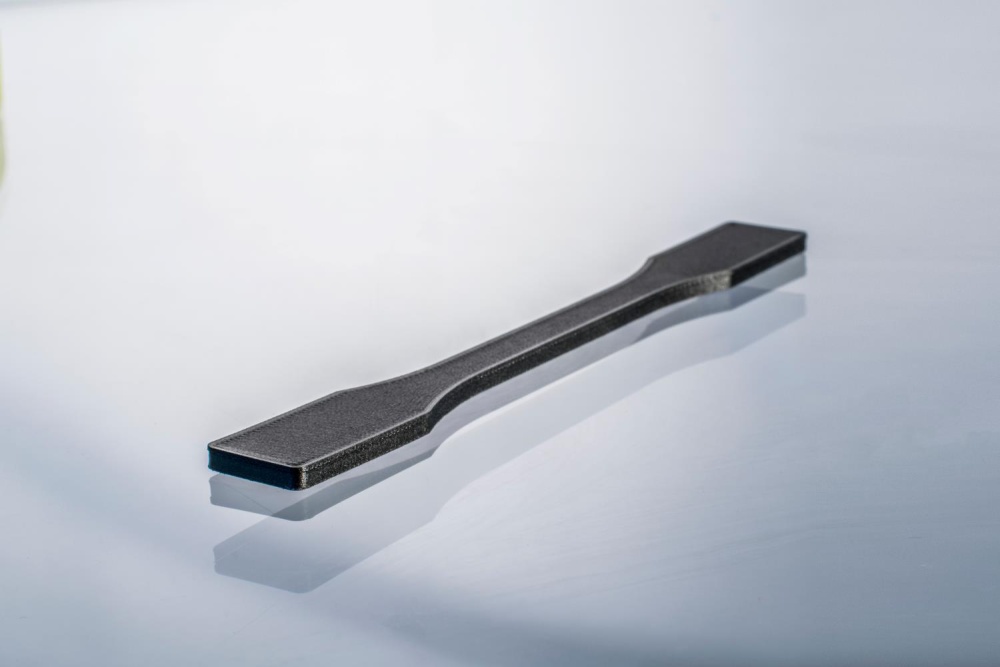

To produce the prototypes we use different materials. A common choice is ABSplus-P430. The material ensures high strength in the printed components. The strength means the components can be used in a “form, fit and function”-test which gives great reductions in cost for the whole developmental cycle of products. Testing on 3D-printed components is a more flexible way of perfecting the finished product as it is relatively simple to make changes and find the right geometry of the products.

Do you need help?

Fill out the form and we will get back to you