APPLICATIONS FOR ELECTRICAL MECHANICAL SYSTEMS

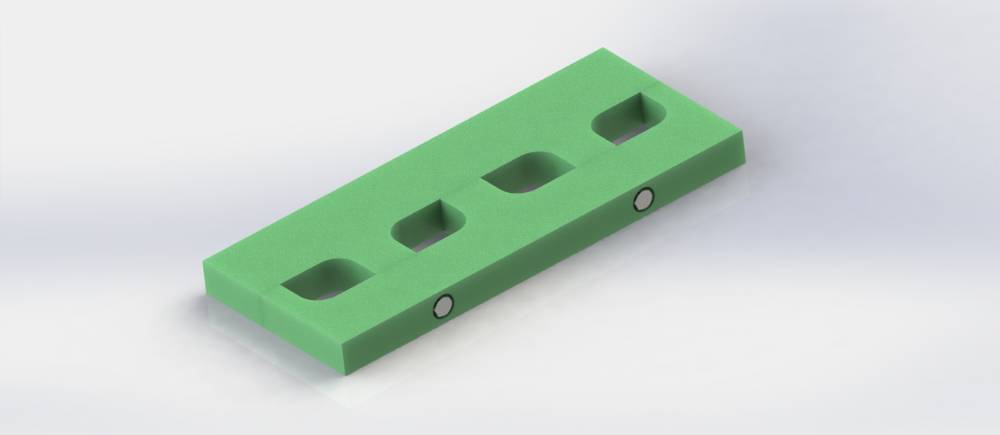

Busbar holders

We produce custom-made busbar holders. They make sure the busbar is held in place separate from other parts and kept away from maintenance personnel for safety reasons, since it is an electrical part, that has a lot of power running through it.

A common material choice for busbar holders is technical laminates which are plastics made with certain additives for a specific purpose. For busbar holders, we use a laminate with additives that makes the material fire-proof.

Customer Requirements:

- Must not conduct electricity

- Fireproof

- Low-cost

Our material recommendation:

- PA66 GF30 (Nylon) - Ertalon

- Technical laminates

Our manufacturing method recommendation

- Machining

- Bulk Compression Moulding for large quantities (around 500+ units per year)

- Sheet Compression Moulding for smaller quantities. (Typically <500 units per year).

Cable clamps

Cable clamps also called cable holders come in all sizes from large clams for holding the main tower cable in place. Down to smaller injection moulded clamps systems for electrical cabinets.

Cable holders have several functions; to keep order, minimize wear and tear from friction bearing and vibration damping.

Plastic is the ideal choice of material as it has low friction, is vibration dampening and have low wear on the cable. Plastic is also not electrically conductive if there should be a break in the insulation on the cable, thus minimizing the risk of short-circuiting.

Customer Requirements:

- Must not conduct electricity

- Fireproof (halogen free)

- Low-cost

- Low wear on cable

Our material recommendation:

- PA6 (Nylon) - Ertalon

- PA66 GF30 (Nylon) - Ertalon

- PEHD

- POM-C - Ertacetal

Our manufacturing method recommendation

- CNC milling for low volume 1-800 per year

- Injection moulding for high production volume per year.

Clear plastic cabinets

Some parts of the controls section in the wind turbine must be visible to the eye, but still shielded off from maintenance workers for safety reasons. We produce clear plastic cabinets and covers for this purpose.

Customer Requirements:

- Transparant

- Material must not conduct electricity

- Fireproof

- Fireproof (halogen free)

- Low-cost

Our material recommendation:

-

PC (Polycarbonate) - Lexan 9030

-

PC (Polycarbonate) - FR - Lexan F 2000

-

PC (Polycarbonate) - FR halogen-free - Lexan F 2500

Our manufacturing method recommendation

- Cold bend PC sheet

- Vacuum forming

Switchgears

A switchgear is a large switch for high voltage which functions as a switch during work in the turbine and as part of the fuse system. In these switchgears highly electrically insulating plates are used to shield contact plates; these can be made of plastic or ceramics.

Technical laminates (see the picture) is a commonly used material, it is plastic with additives to give the material new properties, for example electrical insulation.

Customer Requirements:

- Electrical insulation

- Resistant to high temperatures

- Halogen free

Our material recommendation:

- Fiberglass GPO3

- Technical laminate, paper and glass laminate.

Our manufacturing method recommendation

- CNC milling

- SMC or BMC for high production + 500 a year.

Do you need help?

Fill out the form and we will get back to you as soon as possible.