APPLICATIONS NACELLES

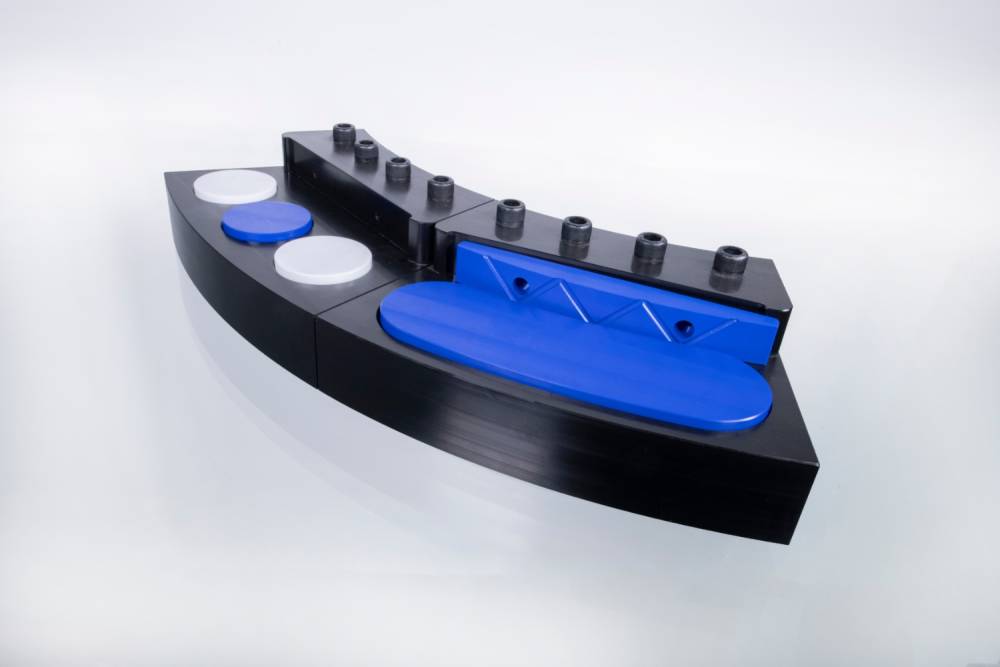

Sliding pads for yawing systems

The yawing system is part of the Nacelle. It allows the turbine nacelle to automatically head into the wind to maximize the power generation.

Plastics are used for the yawing system that turns the wind turbine as the material must withstand friction. This is both to reduce wear on the material and make the movement as silent as possible.

A common type of plastic for this purpose is a version of PA (nylon) often with certain additives to make the material self-lubricating. PETP (Ertalyte) is another common material choice.

Customer Requirements:

- Low to very low wear. Long lifetime

- Low stick-slip which give low noise

- High creep resistance

Our material recommendation:

- PETP - Ertalyte

- PA6 with oil - Ertalon LFX

Our production recommendation

- 5-axis milling

- Laser engraving for identification if required by the customer

Grease trays

Grease or lubricant is used in the yaw system for the sliding pads. The grease cannot be allowed to drop inside or outside the turbine, so a grease tray is needed under the yaw system.

Depending on the system a small tray can follow the calibers around or a circular tray can cover the entire way around the top of the tower.

Customer Requirements:

- Can withstand grease

- Low cost

- Easy to clean

Our material recommendation:

- PP-C

- PEHD

Our production recommendation

- Vacuum Moulding

- Injection Moulding

Covers

Covers are needed for different areas of the nacelle. They can be cost-effectively made with plastic in different forms and are safe for personnel to step on and blocks electric or mechanical areas that can be dangerous for a person to reach into.

Customer Requirements:

- Low cost

- Easy to attach and remove

- UV-stable if outside

Our material recommendation:

- PP-C

- PEHD

- PC (Polycarbonate) - Lexan

- ABS

Our manufacturing method recommendation

- Vacuum Moulding

- Injection Moulding

Bolt covers and thread protection

Thread and bolt heads needs protection from corrosion and impact during transport and during service of the turbine. Plastic covers solves this problem. We offer both standard and customer specific solutions.

Customer Requirements:

- Can withstand grease

- Low cost

- Easy to attach and remove

- UV-stable if outdoors

Our material recommendation:

- PP-C (regenerated)

- PEHD (regenerated)

- Soft PVC

Our production recommendation

- Dip casting

- Injection moulding

Need help?

Fill out the form and we will get back to you as soon as possible